Our Production Processes

PRODUCTION FACILITIES

DUO TEC TAPE EXTRUSION LINES

DUO TEC TAPE EXTRUSION LINES

The process involves a unique double stage stretching in which the tapes undergo a pre-stretch before entering the hot air oven for the final stretch, resulting in better runability and flexibility to improve any one or a mix of factors such as working speed, efficiency, process stability and tape properties.

HIGHER WORKING SPEED

BETTER PROCESS STABILITY

LOW DENIER VARIATION

| Model.E135B Technical Specifications | Screw Diameter (mm) | R135 |

| Maximum Melt Capacity – PP (kg/hr) | 750 | |

| Working Width (mm) | 1400/1600 | |

| Line Speed Mechanical (max.)(m/min) | 500/600 |

| Model.E135B Technical Specifications | Winding Ratio Setting | Electronic |

| Tape Width Range | 1 end 1.2 – 6.0 mm2 2 end 0.9 – 2.0 mm2 | |

| Denier Range | 500 – 3500 | |

| Length of Traverse | 90/82.5 mm | |

| Bobbin Core-Inner Diameter | 280 mm | |

| Winding Speed Mechanical (max.) | 500 m/min | |

| Max. Bobbin Diameter | 280 mm |

TAPE WINDERS

TAPE WINDERS Winding machines designed for winding flat or fibrillated PP/HDPE tapes across a multitude of specifications in terms of tape width and denier. The warp & weft bobbins produced can be used in both circular and flat looms.

Engineered for good bobbin quality at high speeds, our winders are energy efficient, easy to maintain and help in ensuring better loom efficiencies with high quality fabric.

Enhanced ability for winding difficult tapes/yarns

Less wear and tear in traverse unit, thus low maintenance

Back pressure can be optimized centrally through pneumatics

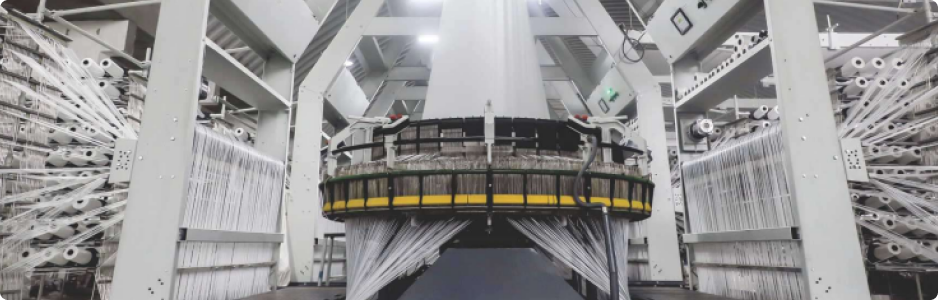

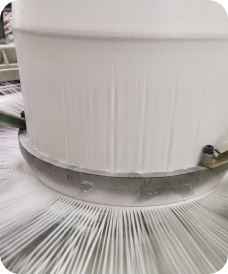

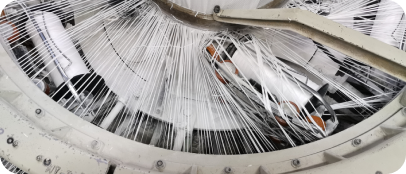

CIRCULAR LOOMS

CIRCULAR LOOMS

ENCORE EXIM LLP is equipped with Lohia corp’s circular loom’s LSL series. Our LSL models represent the conventional circular looms for weaving tubular or flat fabric from PP/HDPE tapes.

We are equipped with 6, 8 and 10 shuttles, these looms are used for weaving light to heavy fabrics, of varying widths suitable for a variety of end applications.

Excellent weaving quality

Low energy consumption

Low maintenance cost

Operator friendly design

| Model.E135B Technical Specifications | LSL6 | LSL610 | LSL620 | LSL8 | |

|---|---|---|---|---|---|

| Working width- Double flat | 30-90cm | 65-110cm | 85-140cm | 150-200cm | |

| No. of shuttles/loom | 6 | 6 | 6 | 8 | |

| Weft insertion rate (max.) | 900ppm | 740ppm | 700ppm | 660ppm | |

| Warp/Weft core internal diameter | 35mm | 35mm | 35mm | 35mm | |

| Warp/Weft core length | 218mm | 218mm | 218mm | 218mm | |

| Warp bobbin diameter (max.) | 130mm | 130mm | 130mm | 130mm | |

| Weft bobbin diameter (max.) | 115mm | 115mm | 115mm | 115mm | |

| No. of tapes- LF | 720 | 1080 | 1296 | 1568 | |

| No. of tapes- HF | – | 1080 | 1296 | 2240 | |

| Fabric roll diameter (max.) | 1200mm | 1200mm | 1200mm | 1200mm |

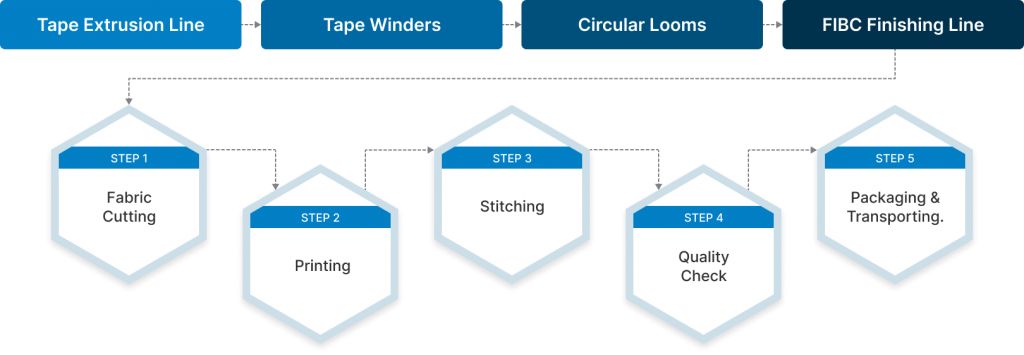

FIBC FINISHING LINE

FIBC FINISHING LINE

FCM 1400 and FCM 2200 are reliable and efficient machines designed to produce FIBC (Jumbo Bags) panels of preset cut length with possibilities of profile cuts customized to client requirements. Fabric pieces of up to 20 Mtr lengths can be cut for other applications as well.

| Model.E135B Technical Specifications | FCM1400 | FCM2200 | |

|---|---|---|---|

| Width of Fabric (max.) | 1400mm | 2200mm/td> | |

| Fabric Cut Length (max.) | 20m | 20m/td> | |

| Profile Cut | O, X, +, U | O, X, +, U/td> | |

| Max. mechanical speed | 70 m/min | 70 m/min/td> | |

| Production speed | 22 pcs./min (with spout) 28 pcs./min (without spout) |

22 pcs./min (with spout) 28 pcs./min (without spout) |

PRODUCTION FACILITIES